By now I quietly acknowledge that my ability to predict the elapsed time to complete a job is woefully inadequate. Rather than quickly knocking off the installatio

n of a new water bladder (flexible water tank) in a few short hours, it has taken twelve hours of effort: three days elapsed time.

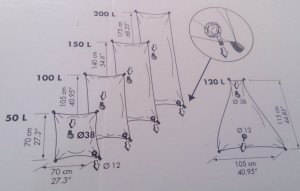

Caro Babbo came with the standard 100 liter stainless steel water tank in port cockpit locker, and a 150 liter Plastimo bladder under the port settee. The bladder under settee can’t inflate fully, so let’s say it has 100 liters.

The weight is enough to make Caro Babbo list to port when she’s fully laden with water.

Rather than merely install a counter-balancing second bladder on the starboard side, I took the time to upgrade the routing of the instrument and power wiring and the diesel line to the Dickinson heater that sat in the bottom of the locker. Rerouting involved buying a right angle drill attachment at Home Depot on Monday, and routing and hanging that fuel line and those wires from the top of the storage locker under the settee.

Now nothing rests on those hoses and cables and it is much neater

looking.

In an earlier post, I wrote that water would get into that locker from the adjacent hanging locker. I also mentioned that we no longer store electronic equipment in there, but did not mention that tools stored there are very rusted. The Nico Press tool is now massively rusty, but that doesn’t really seem to impact its performance. However, the very expensive and very wonderful pop rivet tool is made of a mix of metals and is completely frozen up.

It will be worth the effort to rehabilitate that tool.

Once all the rerouting was done, which required two trips to Fisheries Supply – one unplanned because the fuel line to the heater is 3/8 inch, rather than the 5/16 used everywhere else – the next step was to continue to drill holes for the supply line from the bladder to the water pump.

What I had anticipated as a very difficult task of threading the supply line under the head, turned out to be a piece of cake, taking only a few moments. I then routed the line up over the entrance to the basement, becoming part of a now rather large bundle of cabling, water hoses and a diesel fuel line to the Wabasto heater. Of course, what appeared to be a straight line thread under the galley cabinets turned out to be utterly impossible. A light shined at one end of what I thought was a straight run was not visible from the other end of the run.

My goal had been to connect this line via a third shutoff valve under the

stove with the other two tanks forming a manifold. After spending more than an hour with absolutely no success, nor even getting close to any success, I added a T on the supply side of the water pump.

This took me to the end of the second four hour day – Hilary’s at daycare five hours per day. The boat is 30 minutes away from daycare.

Today, Wednesday, I placed clamps on all of the hose connections and figured out what to do about the filler.

It is customary to place the filler somewhere outside the cabin. On Caro Babbo, the fuel filler and the waste tank pump out are on the outside of the hull on the starboard side. The two water fillers are on the port cockpit seat just forward of the cockpit storage locker lid.

I could find no satisfactory way of running an inch and a half filler hose anywhere that made sense that did not make that hose very visible and in the way.

I decided instead that, at least until we get back from our trip in October, the filler would be inside the main cabin. I had originally envisioned the filler mounted in one of the covers of the storage area that now contains the bladder. I went so far as to make a replacement cover that I would be comfortable cutting a hole in. It was part of the time spent on Tuesday. I used a table saw and bench sander in the shop to make the lid.

I bought some very stiff food grade hose at Fisheries, which unheated does not want to bend for love nor money; heated, it becomes very pliable.

Eventually I realized that to place the filler vertically in the storage cover lid would require a significant amount of vertical space inside the storage locker. Instead, I decided that the filler pipe would just lay horizontal on top of the bladder and use the through hull fitting to terminate the hose.

It wasn’t any great surprise to find that both the filler fitting and the supply fitting leaked when the bladder was first filled. I mopped up the leaked water, tightened up the threaded rings that hold the L-shaped hose connectors, and all seems to be in water tight.

The electric pump easily drew water from the bladder.

I capped the day at the boat by ordering an impeller kit and valve cover gasket for the thousand hour maintenance that I hope to start tomorrow (Thursday).

In the spares cabinet were two impeller boxes. One for a Tohatsu outboard – I knew that. The second was for a Yanmar. The surprise was that the Yanmar box was empty.

At 1000 hours, the impeller is to merely be inspected. If it needs to be replaced I will buy a second impeller kit to keep as a spare.

The big job is to re-torque the head. That itself is quite easy, but I’m still not entirely sure whether I need to remove the valve train. The manual also insists that the valves be re-gapped after the head is tightened.

I also need to change the oil, which I’ve done before and is an easy job.

As part of this process, I will install the new mechanical lift pump that I bought a few days ago.

Before leaving the boat today, I started removing the cabinet in the head.

The cabinet is a front frame with two plastic sliding doors, and two shelves behind the frame composing the top and bottom of the cabinet.

In cabinetmaking style, the screws, which are nuts and bolts and therefore need two people to disassemble, have the screw holes countersunk and plugged.

These are not the original plugs as they were a different color and were finished differently than the rest of the cabinet. I mention this because in cabinetry the plug is very thin and easily removed by cracking in the center with a thin screwdriver or small chisel. These plugs were dowels that filled the entire ¾” countersink hole, as one would do on the hull of a wooden boat, and had to be chopped out bit by bit.

The disaster that is the main cabin continues to grow in the static turmoil that is all of the boat stuff stacked everywhere.

This evening I spent $380 on Amazon ordering 100 W solar panel, a MPPT controller and optional display panel, a gallon gasoline container for our 3 hp outboard, two cycle oil, another tentpole set that we will use for the cockpit enclosure and other items totaling 11 items that will be shipped in four different shipments.

controller and optional display panel, a gallon gasoline container for our 3 hp outboard, two cycle oil, another tentpole set that we will use for the cockpit enclosure and other items totaling 11 items that will be shipped in four different shipments.

I also found a company, Milltech, that has wonderful prices on the Vespers XB-8000 AIS transponder and associated hardware and cables.

They also have an apparently amazing Lowrance VHF radio that includes NMEA 2000, NMEA 0138 and an AIS receiver for under $300!

They offer a variety of other products, I want to call Milltech to find out if there is anything substandard in this radio.

The days get less done than I would like, but there is plenty to do in the evening. Aside from shopping, I put another coat of varnish on the brightwork at the apartment.

Hi John, I follow your posts with great interest and appreciate that the hard work and minor frustrations are a great diversion from the world of software and selling. I started my early days as a cabinetmaker that later provided me skills used in two major historic home renovations. I somehow got diverted to newspapers, management, and later sales. But to this day, I still cherish the skills and time working with my hands and the challenges to create something tangible. Enjoy the experience and I’m sure you’ll reflect on it as you sail the inside passage.

David

You’ve done it now, David. Now that I know you have this skill, there will be no end to the questions I will be asking you. In a future post I’ll discuss re-veneering the wall and the divider I am currently revarnishing. I’ll ask for your expertise.

When that second person isn’t around to hold a wrench: http://www.amazon.com/Stanley-85-610-10-Inch-MaxGrip-Adjustable/dp/B00009OYGZ/ref=sr_1_1?ie=UTF8&qid=1458066269&sr=8-1&keywords=locking+adjustable+wrench

Terry,

The price is quite good and it is a Stanley product. Is the quality as good as I would expect? Do you have one?

I have one onboard that you can check out. The quality appears to be pretty good. It’s paid for itself on many occasions when I needed a second hand to hold a wrench.

I recently saw that Hardwicks has them in stock.

Nice looking wrench. Like a vise grip but won’t mar a nut or bolt head, and should stay on.