Point Hudson, WA 4-FEB-2025 – The steering wheel on Caro Babbo has wiggled since, perhaps since we got the boat. There were times when I thought it might come off in my hands, or worse still, Jennifer’s hands. I thought about how I could steer with the sails, or with a wrench attached to the rudder post. Eventually, I had an emergency tiller fabricated in Hawaii.

But, most of the time, I knew it was just a bushing that had worn through. I didn’t know what the inside of the steering mechanism looked like. Like most things, until you’ve seen one, which I hadn’t, you’re frightened by what might be there, or when taking it apart what might pop out never to be found or reassembled again.

Replacing the bushing was on my list for this fall. It was on my list for this summer, but I chickened out fearing it would take weeks to repair.

This past Monday I took a wheel puller and pulled off the steering wheel. I’ve done this before to replace the autopilot, and then took a screwdriver and disassembled the steering mechanism.

The actual mechanisms are two push-pull cables that move the quadrant on the rudder post. There is no play in the system. I’ve never understood the system with chains and springs.

The mechanism is held between the cables under the cockpit table. I disconnected the box from the table and then started to disassemble the box. The cable housing has enough spring that the box could easily be pulled away from the face of the table and be worked on.

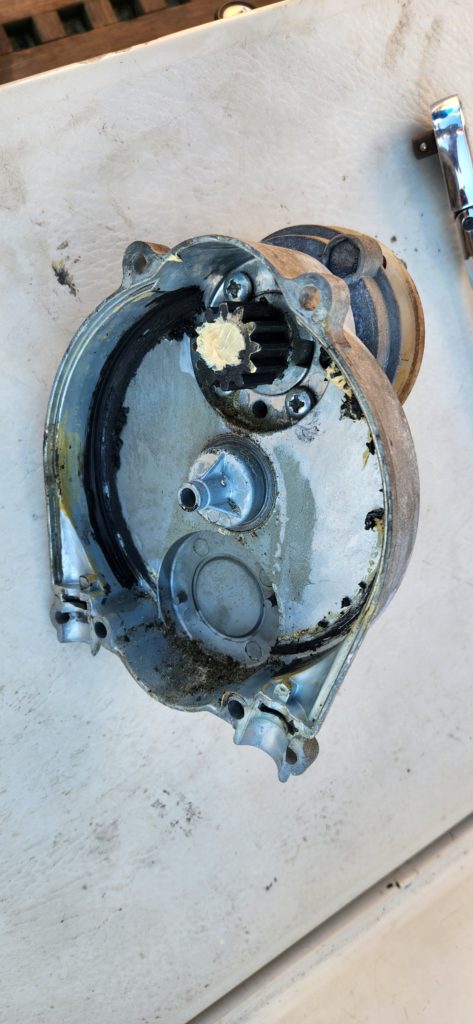

The screws outside are large and easily removed; the inside is greasy: wear gloves. The mechanism is a gear attached to the spindle the wheel is attached to, which engages the teeth inside an eight-inch wheel (17 cm, approx). The cables are attached to the outside. When the eight-inch wheel moves it pushes one cable and pulls the other. That’s it.

I removed the slip ring, and the key and pushed out the shaft from the front of the mechanism. There they were two nylon bushings that had worn through. Now off to my favorite machine shop, Andersons.

Andersons are Icelandic, not Swedish as the name led me to believe. I first spoke to the young man five years ago about some mast fittings I needed done. I asked about his name. In Iceland, girls have surnames that end in daughter and boys are sons. What is his family doing? They just settled on son and have left it like that.

He also wanted a few hundred for set up and $75 a part. I couldn’t afford that. A few days later I stopped by and he offered $75 setup and $75 a piece. I bought three of each piece.

This time he told me it would be an hour of his time. ‘‘It should be done in a week.’’ I told him I’d call him in ten days if I hadn’t heard. Four days later, it’s done and all movement is gone: $161 with tax and no removing cables, etc.

Putting it together was just as easy. There is no wiggle any longer.

Oil pressure gauge

The oil pressure light stopped working just outside of Hoonah on the way south this year. I think I noticed it when we stopped for fuel on the way into the city harbor. The light comes on with an alarm whenever there is low oil pressure. Whenever the ignition system (the Key) is turned on and tyeh engine is not running, there is no oil pressure hence the light and the screaming alarm. It is very annoying. This time nothing, no alarm screaming no il light. But the gauge worked.

So no need to worry other than should the oil pressure drop there would be no alarm. The light stopped working in late July 2024.

The gauge, though, has an annoying problem because the reading is not consistent: it bobbles at certain times. It is unnerving, even though it never drops into any danger zone. The oil pressure gauge is a plunger type and I guess either the spring is going or the internal connection is faulty, so I changed both the pressure light switch and the gauge sending unit. A new pressure switch was very easy to find: An NPT thread and the part is listed for this engine.

The sending unit took a moment because 3GM30F engines don’t come with oil pressure gauges, but Volvo Pentas do, which was the original engine in this boat. I looked for and found the sending unit. Taking off the two sending units required removing the entire T the two units were attached to after first detaching the gauge sending unit.

The oil pressure light switch stopped working because the connector at the end of the wire broke off. The unit itself was so rusted that I replaced it. I attached the new switch, the connector, connected everything and we’re back in business.

However, the engine is hard to start now. I left it five months without starting it and it is now difficult to start whenever the engine sits for more than a few hours. I have three months to solve this.