1-OCT-2016 – It’s easiest to answer the last item first. Yes, a number of things did not break. None of the standing rigging had any sort of failure (the standing rigging is what holds up the mast). After that it becomes a little more difficult to think of something, None of us, personally, were injured or became ill, nor did any of our guests, so the human factor held up well.

It’s better to move onto status and statistics and return to what broke at the end.

Status

We’re in Seattle preparing to fly to Phoenix with Hilary and two Maine Coone cats.

We’ll be in Phoenix, nominally, until January 7th. Jennifer will be in Atlanta for a couple of weeks and Berlin, Germany for a couple of weeks.

When we return to Seattle in January, we must finish the 50 or 60 items on the to-do list including pulling the boat out of the water (putting it on the hard in boat speak), putting anti-fouling on the bottom, inspecting the propeller (called the wheel by commercial mariners), the rudder and the through hull fittings.

Jennifer and I each lost weight, though I gained back a bunch while Sarah and David visited us.

Hilary gained weight.

Jennifer and I each lost muscle mass and our cardio abilities dropped. We had planned on rowing each day during the trip, but such was not to be.

Statistics

Here are a few statistics, that might amuse you:

- We used about 70 pounds of flour, close to twenty of those during the two weeks David and Sarah visited us.

- We anchored 110 nights out of 150, many less than expected. More than fourteen can be tied to our mechanical breakdowns.

- We motored for 598 hours. More than I had hoped, but in line with what was predicted.

- We spent about $1300 on fuel.

- We had parts airfreighted to us four times.

- We spend approximately $1000 on engine repairs – parts and airfreight only, no labor. Of those, it looks like only one wasn’t caused by me.

- We never ran aground, never needed to be towed.

- We made more than fifty blog posts.

- We had six different people and one dog stay with us on the trip. We had guests 21 nights out of 150.

- We went out to eat

foursix times. - We changed the engine oil twice, fuel filters five times.

- A clogged fuel filter stopped the engine once.

Items that broke and the status of those items

In no particular order:

- Webasto Forced Air Heater – Overheating alarm stops operation of heater. This failed consistantly during the trip after the first few weeks. On returning to Seattle, it is now working. This is an intermitent failure. The worst kind of failure. The strength of the Webasto is that it starts immediately, as a forced air heater it sends air into both the aft and main cabins, and it is controlled by the same type of thermostat that we all use in a house or apartment.

- Mounting for Webasto Heater – The mounting, which came with the boat – I want no blame for this, I’ve made enough mistakes without taking credit for other’s – was made of a cutting board constructed of individual lengths of wood. Screws to mount the heater did not share any lengths of wood with the screws that held the mount to boat. When the glue finally failed, the mount fell apart and the heater was held up solely by the lines and hoses needed to run the heater. This has been (unsatisfactorily) repaired.

- Mainsheet traveller car – The wheels on the car have started to disintegrate. The entire car, but hopefully not the track, needs to be replaced.

-

Melted 12-volt plug for laptops. 12-volt connector for laptop power supply melted. It, most likely, was not pushed in securely. We cut off this plug and spliced on a new one.

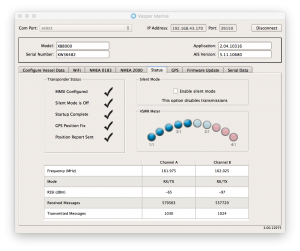

- AIS stopped working – We believe a firmware issue caused the AIS to send out garbled messages – Everything indicated something was being transmitted. Upgrading the firmware fixed the problem, though Vesper, the maker, said this firmware contained no fixes related to our problem.

Although Vesper said this screen capture indicates it is transmitting, no one received the signal. Unrelated firmware upgrade fixed the problem. - Windvane – The windvane self steering was to have had its installation finished and the unit to be tested and used on this trip. When we went to make final adjustments to the unit, we found a previous owner had epoxied the parts together so they could not be adjusted. I had planned to remove the epoxy by heating the parts, but never did.

Even while things are breaking, we get to see sights like this. - Steaming light – The steaming light is the light on the front of the mast. It is used when the vessel is under power in the dark. I brought a replacement unit to install when David and Sarah were with us. The mounted unit was working fine when we left in April, but was getting old. Sometime in May it literally disassembled itself on the mast. We mounted a second white light on the spinnaker pole mounting ring to compensate for its loss. The new light still needs to be installed.

- Stern light – This was broken, we think, when the dinghy hit the transom in a following sea, or perhaps someone stepped on it getting into the dinghy.

- Toilet – The joker valve clogged and was replaced from spares. We found the plastic mounting points for the pump handle are failing and need to be replaced.

- Holding Tank fullness sending unit stuck – The sending unit must be removed, cleaned and reinstalled. Jennifer has volunteered to be away from the boat when I undertake this.

- Zinc – When we were using Derek’s GoPro to inspect the propellor, we found that the zinc used to prevent electrolisis was missing. Our prop is made from bronze so the worry isn’t as great as if it was made from brass. I replaced the zinc by diving under the boat.

- The float switch for the automatic bilge pump has failed. We have temporarily bypassed the switch so the pump can be turned on by inserting the fuse into the circuit. A new switch needs to be installed.

- The reading light over Hilary’s bed stopped working – To turn off the light, Hilary twisted the LED light, which shorted out the circuit taking out most of the cabin light along with it. I straightened and shortened the leads, so twisting it would be more likely to remove the light rather than short out the circuit.

- Engine –Sheared Bleed Screw – This is a side effect of the air leaking into the fuel line. When I sheared off the bleed screw we were sent on to the adventure of the trip. Taking the 3hp engine as a safety measure paid off. You can read about the adventure here.

- Engine difficulty starting – Air is leaking into the fuel line as the engine cools. This problem has plagued us since before the beginning of the trip, though we did not know what it was. The remedy is to bleed the fuel line each time before we start the engine. It had gotten to the point where it is no longer a nuisance, just part of the process. A longer description is part of a technology post written during the trip.

When water siphons through the orange hose after the engine has stopped, it can fill the black hose, eventually backing up into the engine. Water does not compress, meaning the engine cannot start. - Engine won’t turnover – After misdiagnosing the problem as a weak starting battery, we figured out it was a water lock – very bad for an engine – caused by the anti-siphoning line for the exhaust becoming clogged because I had installed a line that was too long and not vertical for its entire run. A longer description is here.

- Engine high pressure line splits – One of the high pressure lines from the injector pump split because I did not reinstall the clamp after some engine work. As I wrote here, the clamp was defective, which is why this particular line split. But not reinstalling the clamp made this type of failure inevitable.

Dinghy on the beach near Friday Harbor enjoying the first attempt to stem the voluminous leaking. - Dinghy leaks – The dinghy leaked very badly when we started the trip, enough so that at the end of a day towing it, the dinghy would be completely full of water. The dinghy turned out to have been converted to being a sailing dinghy. A few mistakes were made in the conversation including not bedding the centerboard well. The dinghy flexes so the center board well (the slot the center board slides into so it can stick out beneath the dinghy and act as a keel) needs a flexible cushion, or a boat that is rigid along its own keel. In general, the conversion was made by assembling the pieces necessary and running some fiberglass over the joint between the boat and the pieces – no adhesive between the two. In places the tape was not impregnated with resin, so it was both weak and not waterproof. My mistake was not to follow marina-mate Derek’s advice and slather the entire joint between the centerboard well and the boat with 3m 4000 marine adhesive, rather than just at the apparent leaks.

The hard bottom paint did not foul after five continuous months in the water. (Caro Babbo’s held up well after three years.) - Dinghy Rigging fails/Mast Step Fails – We generally towed the dinghy with the mast up in the hope that we would quickly put up sail and sail in one of our anchorages. The standing rigging was a mix of 1 by 19 Stainless and a piece of Dyneema. The stainless was fashioned with Nico Press collars, one of which was not crimped properly and slid loose on a shroud. The pressure of the mast jerking from side to side broke the fiberglass tape at joint between the step and the hull. The was no adhesive holding the step to the hull. We took down the mast and called it a day. We’ll make a decision about whether leaving the dinghy as a sailing dinghy or returning it to its initial non-sailing state in January. BTW, the hard bottom paint we put on the bottom of the dinghy worked wonderfully: the dinghy sat in the water five continuous months and came out clean.

- Flexible water tank leaks – We bought Caro Babbo with a stainless steel 100 liter water tank under the port cockpit locker and a ‘‘flexible’’ 150L water tank (a bladder) under the port settee. The boat listed to port when fully watered and fueled because of this (Caro Babbo is 8000lbs dry, 300lbs of water makes this difference). Also, an additional 150L of water would be welcomed. I installed the bladder under the starboard settee before we left, and no matter what I did I could not get it to stop leaking at the drain… Or so I thought. The bladder is very heavy polyethylene in a woven cover from which it can be removed. After three months of leakage, I finally gave up, removed the bladder on the Native Brotherhood dock in Sitka, pulled off the cover and discovered that there was manufacturing defect: a small leak next to the filler. The water could only exit the cover at the drain…finally, something that I had no hand in causing. When we returned the bladder, the importer (Bainbridge) replaced the entire unit at no cost. The new one is installed and does not leak.

- Starboard running light stops working – The power to the bow running lights runs along the starboard side of the hull, splitting in the bow anchor/sail locker to power the port and starboard lights. The wires are held out of the way with the original plastic wire tie blocks, which are nailed into the fiberglass – this is done throughout the boat. One of the tie blocks came loose from the hull and the crimped connection was broken by the 135% genoa that is stored there. I replaced the connection with a terminal block that can be easily inspected, but is currently not attached to the hull. While debugging the failure, I found that after forty years the plastic on the starboard (green) running light is starting to fail from UV damage. The same lights are still made, so I think I will replace them with the same units.

- Engine stop has failed – Well, it was inevitable that after all the things that keep or start the engine running have failed, the piece that stops the engine would fail next. The cable from the cockpit that stops the engine by cutting off fuel jammed. To stop the engine is merely a matter of opening the engine cover and pressing the lever by hand. I’d prefer to find why it is jammed and fix the jam, but replacing the entire cable isn’t too big a deal.We eventually learned that the kill cable was strangling the engine by restricting fuel – not before I rebuilt the injectors, which needed to be rebuilt anyway.

- Engine won’t fully power up – This started the day before we arrived home. The engine will rev to red line in neutral and reverse, but not in forward. Why full speed in reverse but not forward? Transmission issues I thought. According to our marina-mate Nate, ‘‘reverse is nothing but cavitation.’’ Forward actually requires torque. So far, the engine revs drop by different amounts depending on which injector we loosen the fuel line to. Smaller drop is in the rear cylinder, biggest drop in the front cylinder. Perhaps this is related to the water lock from the anti-siphon failure.

- External disk drive and back up fail – New macs have rather small Solid State Drives (SSDs). The contents of the previous mac internal drive are spread onto an external drive, which failed. Then the backup software erased the backup. There is a safe backup in Seattle, which is taking many days to restore rather than the four hours it should… but it seems to be working.

- Binoculars – We dropped not one pair, but two pair.

- Inverter – An inverter converts 12V DC to 110V AC. We used the inverter to power the sewing machine and charge some things that only have 110V AC chargers. We haven’t missed the inverter very much, but will replace it in the spring.

- Shear pin – You know, taking an outboard through rapids with visible rocks is inherently risky. And if you do, take a replacement shear pin with you. We did not. The amazing people at Bridgeview Marine in Price Rupert delivered the parts to us at the marina, free of charge. Such wonderful people: they extended the delivery service to their commercial clients to us. And, after the shear pin shears, you might find yourself sideways on a rock, but knowing that the tide is rising and will float you off is a great comfort.

- Stove – over and over. The jury is out on the stove. At $3100 USD, it may have been an expensive mistake or just that I don’t know how to maintain it. The vendor is going to rebuild the burners for free. He says that it is only necessary to service the stove after many hundreds of hours of usage. Our experience, and recommendations on the web, seem to indicate the burners should be serviced after every twenty or so hours. Servicing is quick and takes less time than cleaning the stove. Or so it seems. We’ll learn more after John Gardner receives the burners in the UK. The stove deserves and will get a post of its own.

- Pump for Dickinson Newport Heater – I had rebuilt this pump soon after we acquired Caro Babbo. The bellows had started to leak. The same thing happened again, about a year or so ago, and now on the trip. The replacement pump, which I bought from the same company, no longer uses a bellows. We’ll see how long it lasts. $107 USD

Posted 17-OCT-2016. Sorry it took so long to get artwork for this post. See item #24.