… Along with what failed.

Since the beginning, owning Caro Babbo has been a preparation for going offshore. We’ve sailed the inside passage to Alaska three times, adding more difficulty each time. On the second trip, we crossed Hecate Strait to Haida Gwaii, on the third trip we sailed down the outside (Pacific Ocean side) of Vancouver Island.

Over the six years we’ve owned Caro Babbo before sailing to Hawaii we made, literally, hundreds of changes. In this article, I’ll talk about the changes that are specific to bluewater sailing, though to be honest, the list will probably be only those changes that I made most recently, or had some traumatic event, difficulty, or expense associated.

If you are looking for structural changes or major changes that made Caro Babbo ready for bluewater sailing, you will be either very pleased or disappointed. We made none. In my opinion, a Maxi 95 is ready to go, from that point of view. The encapsulated keel removed worries about keel bolts (later boats have keel bolts, which ruled them out for consideration – some people prefer bolt-on keels), the buoyant bow, flush deck, and compression-post mast, along with the shroud attachment points are all strengths. Lack of backing plates on the backstay was an issue that we addressed.

Finally, just because we took a Maxi 95 across the Pacific Ocean doesn’t mean it is a proper boat with which to do so. I think it is a proper vessel, I wouldn’t have done so if I thought it would be unsafe, but it doesn’t mean it is safe. Please make your own decisions about doing such a thing.

A Note: when we bought Caro Babbo, she had an Isomat mast, which we have kept. The Isomat mast is half a metre taller than the stock mast. I thought the standard mast was lighter weight than I would have liked, so I was pleased to have this mast with its heavier wall thickness, welded fittings, and heavier standing rigging. I make some references to this mast below. Would I have gone to sea with the original mast? Probably.

If you’d like to send me email about this article, click this link.

What we Added or Changed

Sail cloth weight, reefing and a storm sail

Caro Babbo does not have roller reefing. This allows us to carry specific sails to meet the sailing conditions. We carry 90%, 135% and 170% headsails, a storm sail, and a spinnaker that we fly with a sock.

In preparation for going offshore, I replaced the main and 135% with 8.5-ounce offshore-weight sails properly measured for the new mast and with the same area. We added a third reef in lieu of a trysail.

In Hawaii, I also added additional reefing rigging to the boom so that all three reefs are rigged all the time. On the San Diego-Hawaii leg, the mainsail had three reefs, but was only rigged for two. We did use the third reef in preparation for weather that never came, and while it is common to re-rig in order to use the third reef, I decided that I would prefer to have all three rigged.

To use our sails we always have the 135% hanked on. We slide it into the forward sail locker when it is not in use, so that we ‘‘go through’’ the 135% whenever increasing or decreasing the sail size. (I will discuss how we change headsails in another article.)

Electrical

Long ago, we replaced all of the lights with LEDs. In preparation for the California-to-Hawaii leg, we upgraded our solar panels to 320W by adding a flexible panel on top of the dodger. The flexible panel has worked very well, and I believe is a great improvement over rigid panels. A flexible panel does cost more than a rigid panel.

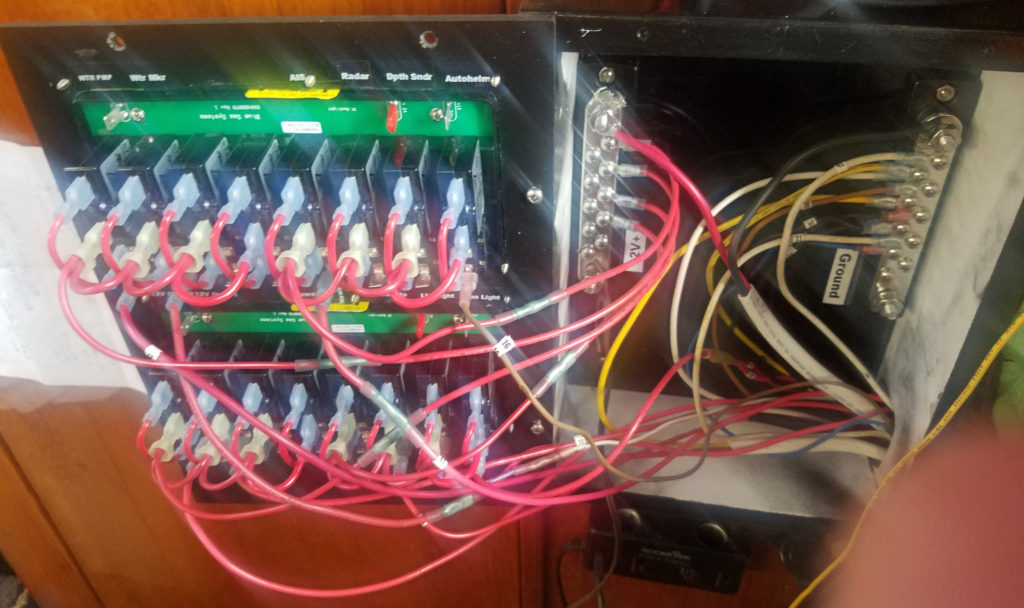

We replaced the fuse-based electrical panel with a waterproof circuit breaker panel. The original, small fuse panel that was shipped with our boat is still in place.

Electronics and communications

Years ago we added a Vesper AIS transceiver and replaced the VHF radio with one that has an AIS receiver and DSC. In the last year, we also bought a handheld VHF radio.

We bought an Iridium Go for satellite communications, which is a game-changer, and single point of failure. We will buy a second Iridium Go as a backup in the future.

The Iridium Go is an old, albeit pretty bullet-proof piece of hardware. The associated Iridium software generally sucks. The Iridium Go can act as a WiFi router, but not as a device connected to a router. As a result, we use it as the router for the entire boat.** All WiFi devices connect to the Iridium Go, but when we need to access the internet, we must disconnect and reconnect to a different WiFi network.

We have not bought a chart plotter or any other integrated system. Instead, we buy the pieces we need to use the open architecture of the NMEA standards.

We use two Galaxy Tab Active2 tablets, SM-T390. One is 16 GB, the other 32 GB. The 16 GB is much too small and will be replaced. The tablets are waterproof and work while wet. However, if the charging port gets wet the tablet will not charge until the port is completely dry. This can be many hours.

I replaced the old Raymarine ST 4000 autopilot with the new EV1. The EV1 electronics are quite marvelous. It talks NMEA 2000, which allows it to communicate with other devices on the boat. In the case of Caro Babbo, there was only one other device that talks NMEA 2000: the Vesper AIS.

Among the Vesper AIS’s wonderful features is translating between NMEA 2000 and NMEA 0183 in both directions.

We replaced our JRC radar with another JRC radar sold under the SI-Tex name. These are older technology systems that still use a magnetron.

It was probably unnecessary to replace the radar dome. Although the new unit is 1 foot (.3m) in diameter, versus 9 inches (.23m) in the previous unit, when I looked at the angle of the smallest detectable target, it was the same. I believe it would have been sufficient merely to replace the display.

This radar display is a vast improvement and shows AIS targets when connected to devices that transmit AIS target information, lat and long, and bearing information (the magnetic direction the bow is pointed).

The Vesper AIS transmits, among other things, course made good (CMG) true, and speed over ground, which the Raymarine EV 1 will also display. The Vesper AIS also transmits all of the AIS data over NMEA 0183 (RS 422), NMEA 2000 (CANBUS), and WiFi.

The SI-Tex radar uses the bearing information from the EV1, together with the AIS target information to display AIS targets overlaid on the radar screen.

Heating – we made no changes, but this is what we have:

Caro Babbo is a Pacific Northwest boat and came with what is standard and necessary for high latitude sailing: two diesel heaters. The Webasto forced air heater is a wonderful, luxuriant device that uses a residential-style thermostat to control the temperature in the cabin. It, however, uses a lot of electricity.

Our second heater is a Dickinson Newport fireplace. As we have it installed, it uses a low-power fuel pump, but it can be easily installed with a gravity feed tank, then it will require no electricity. It has only two settings: off and full furnace mode. The manufacturer recommends opening hatches if it becomes too hot in the cabin. The Dickinson does not lend itself to heating while underway, while the Webasto is perfect for use underway.

Water independence

We added two 150L (40 US gal) water bladders, one under each of the two settees in the main cabin. Because of the shape of the space, they only hold about 100L (26 US gal) each.

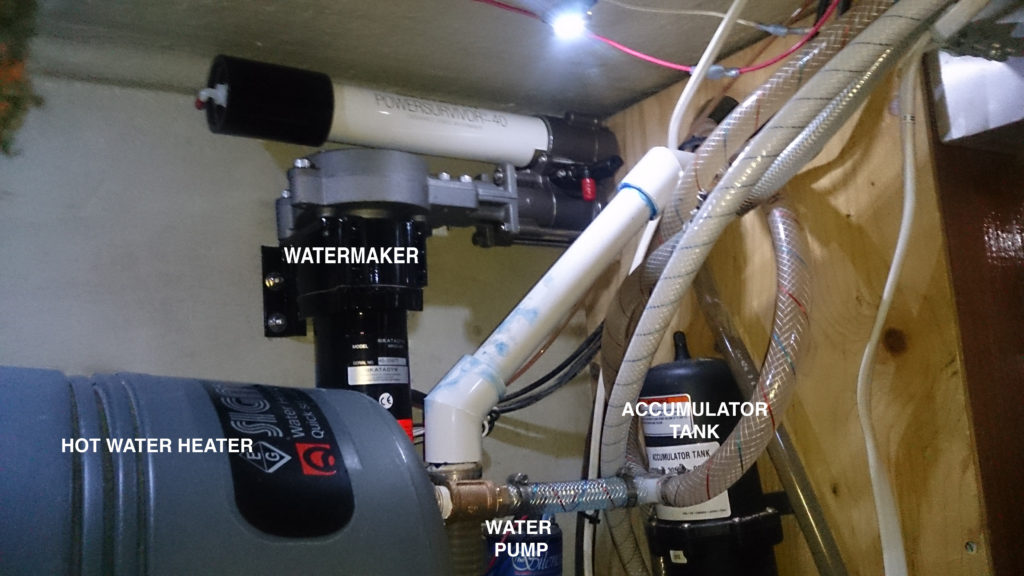

To give us water independence, we installed a Katadyne PowerSurvivor 40 water maker, which uses 25W of power, producing 1.4 US gallons (5.3L) per hour. It is usable when powered by solar panels. This has been a remarkably bulletproof device and a real game-changer. We’ve cruised for weeks without touching either of the water bladders.

Safety equipment

We bought a type I EPIRB, which will self deploy if submerged.

We each wear AIS crew-overboard beacons attached to our PFDs. We also wear harnesses with crotch straps.

We do not use inflating PFDs.

We have taken the approach that, to the degree possible, we do not want to be dependent upon devices that we will only know whether they actually work when our lives depend upon them. The type III PFDs we wear also provide 1 inch of foam insulation under our jackets in cold weather; it seems that whenever we are above 40° north, it is always cold.

We added 1/4 inch (6mm) Dyneema jack lines encased in yellow nylon webbing that run from a pad eye just aft of the anchor locker to the cleats on the transom. Except when in warm water, very close to shore, we are always clipped into the jack lines, even in the cockpit.

Life raft

Keeping with my philosophy that I do not want to find out whether something works when I need it to save my life, we decided to go with a Portland Pudgy, which is a SOLAS liferaft and takes care of two things at once.

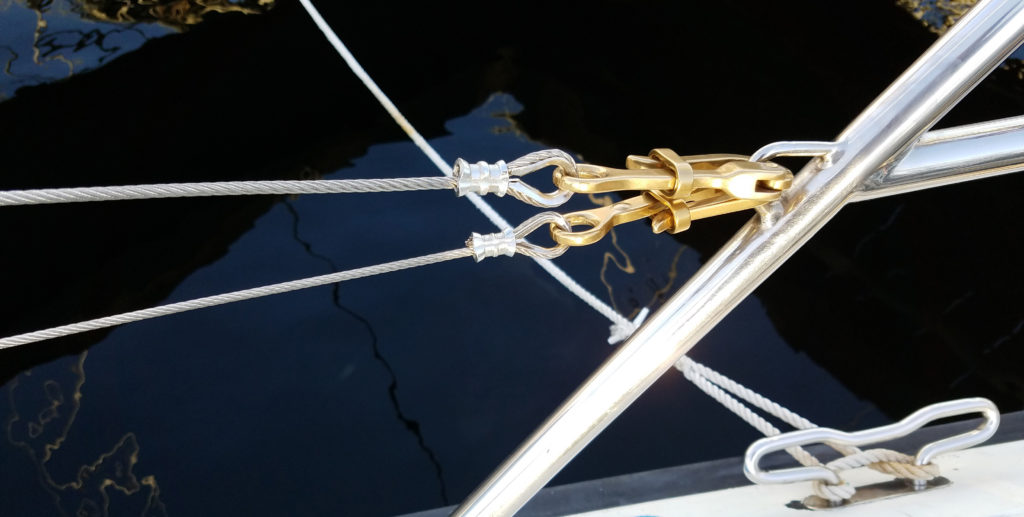

At 7 feet (2.1m) long, the Portland pudgy will fit on the deck of a Maxi 95, if the baby stay is removed. On early hull number Maxi 95s, the shrouds are connected to a steel ridge that runs along the deck. We attached two forward shrouds to this ridge†, which gave us enough space to place the Portland Pudgy upside down on the deck. The Pudgy is tied down with straps connecting to the same pad eyes as the jack lines at the bow of the dinghy, and to the links for the shrouds at the stern of the dinghy.

On the advice of the Portland Pudgy manufacturer, we installed pelican hooks to easily detach the lifelines to allow the Portland pudgy to slide easily over the side boat behind the pulpit.

Self Steering, Emergency Rudder and Emergency Tillers

We also added wind vane self-steering. I wanted a servo pendulum device that also had its own rudder. I was able to find an old Sailomat 3040 that was made in Göteborg, Sweden in the 1980s.*

While the installation instructions for many servo pendulum devices state that the device cannot be mounted off-center, it is only because when heavily heeled, the pendulum oar may not make contact with the water. Many of those pendulums swing more than 100 degrees. The 3040 pendulum swings only about 40°.

Note that both the rudder and the pendulum add drag. Because our Sailomat 3040 is off-center, the wheel needs to be turned to compensate for the off-center drag.

When we are using the electric autopilot, we remove the Sailomat rudder and oar from the water.

Using a wind vane for self-steering is a truly magical experience. The device is completely silent and the boat follows the wind so that it is not necessary to constantly adjust sail trim. Of course, unlike a self-steering device that follows a heading, a wind vane will take you off course as the wind shifts.

The rudder on the Sailomat 3040 is also our emergency rudder.

I had emergency tillers fabricated for both Caro Babbo’s rudder and the Sailomat’s rudder.

Drop boards

The doors on a Maxi 95 have two problems. The first is that doors are binary: they are closed completely or open completely. The second problem is that the Maxi 95 does not have a bridge deck, meaning any water more than 2 inches deep will flow into the cabin if the doors are open.

I implemented three drop boards of 12 mm clear acrylic. The bottom drop board is the height of the seat and plays the role of the bridge deck. The second is the height of the cockpit combing and can be easily climbed over when entering or exiting the cabin. The third is the height of the doors.

The drop boards are installed on the outside of the companionway, allow us to keep the very convenient and attractive teak doors, and are held in place with toggles using spring washers for tension.

We never needed the drop boards, and never even installed them underway. Though we have never had more than a splash enter the cockpit, we’re ready.

Access to Drains

I cut half-moon shape openings along the outside of the cockpit grating to give access to the cockpit drains. As we received Caro Babbo, the drains were completely covered by the grating. Water could only slowly find its way to the drains by seeping under the grate. The half-moon cuts are not enough, but are what seems feasible. I expect that if the cockpit really needed to drain quickly, I would jettison the grates.

The drains on our 95 are 1.5″ (38mm) inside diameter, the opening from the cockpit floor is a narrow opening and insufficient if the cockpit flooded. Having said that, we have never had a wave break into the cockpit. I think this is a combination of good weather planning, and the hull and deck configuration of the Maxi: center cockpit, and buoyant bow and stern.

Second Bilge Pump

We added a second automatic bilge pump while in Oahu. This bilge pump is a diaphragm-style pump that sits in the port cockpit locker. The intake is directly under the prop seal and allows us to completely empty the aft-bilge, something an impeller-style bilge pump can not do.

On the Kuaui-Aleutians passage, one bilge pump failed, and the electronic float switch on the other failed. We used the manual bilge pump switch to empty the water that was coming in through the leaky propeller seal.

Windows

We replaced each forward window with three dark polycarbonate windows. We kept all the screw holes and drilled over-size holes in the windows to allow for independent expansion of the hull and the windows. We bedded the windows in Bed-It-brand butyl rubber. The windows have never leaked a drop. (We were shocked to discover how much the previous windows were leaking what we thought was condensation.)

I did not replace the windows in the aft cabin.

NB: The window openings are not symmetrical side-to-side. I made the assumption that they were.

Windows this size and larger are common on sailboats these days and I feel the polycarbonate will withstand Caro Babbo being slammed on her side. What I should have brought along are premade shutters to block off a window that gave way, rather than the material to build one quickly… or should I have?

Halyards

We replaced the main and headsail halyards with Dyneema halyards with a polyester tail. I did all the splicing. We also added as many halyards to the mast as there were sheaves. This gave us four forward halyards at the masthead and two aft halyards at the masthead. One aft halyard is used as a topping lift.

I also replaced any running rigging that was showing signs of wear, which included the sheet used for the 90%, 135% and the storm sail, the boom vang, the reefing lines, and the mainsail outhaul all with brightly colored braided polyester. The 170% has its own set of sheets.

Backing Plates

None of the Maxi 95 deck hardware comes with backing plates. We added backing plates under the aft cleats and the eyes that attach the backstay to the stern rail.

The deck hardware that we installed (midship cleats and forward pad eyes) has backing plates.

The wind vane installation was a trial installation that became permanent. There are no backing plates behind the wind vane, but we have never seen any deformation of the transom even in heavy weather.

Because I did not install the wind vane to the transom with Loctite, we periodically needed to retighten the bolts by hanging over the stern. Loctite fixed this problem – lock washers were insufficient.

Nylon Rode

I can’t imagine a 95 with two hundred pounds (91 kg) of chain in its bow locker. I had planned to remove our 11kg Rocna anchor from the bow for the trip. The one time I did, I could feel the difference in the boat. We keep 30 ft (9m) of chain and 210 feet (64m) of ½” (12mm) nylon line in the bow locker.

Dyneema Shackles

We have replaced many of the metal shackles with Dyneema. These shackles are very easy to make, very inexpensive, and are easily removed and reinstalled. The shackle that connects the mainsheets to the traveler is a Dyneema shackle. We detach the mainsheet from the traveler at anchor so the cockpit is more open and we can set up a shelter using fibreglass tent poles.

What we want to Change

Alternator

Caro Babbo has the 3GM30 stock, 40 amp alternator. The next model engine produced by Yanmar has an 80-amp alternator. If it will fit, I would like to upgrade to 80 amps.

What Broke

On the trip from Seattle to San Diego, and then on to Hawaii, things did break. I had a sense of how many, but not until I spent time considering this part of the article did I realize how many. Only when we arrived in Oahu did we realize how typical this. Many more things broke from Seattle to Hawaii, than broke from Hawaii to Alaska. But, then, as has been said, ‘‘the only proper shakedown for a 2000-mile voyage, is a 2000-mile voyage.’’

The largest problem was the self-steering gear. 50 miles outside the Strait of Juan de Fuca, the sacrificial coupling on the wind vane oar broke.

We used the electric autopilot to get us the rest of the way to San Diego and it worked quite well.

While anchored in the channel islands off the coast of Los Angeles, the quadrant worked its way loose. We found that the quadrant was constructed in such a manner that the needed tightness on the quadrant deformed too much of the quadrant to work well. It also needed a “stepped” key. The machine shop gave us a very high tensile strength, fine threaded bolt to deform the quadrant as necessary to tighten it up.

We had a new sacrificial coupling and a stepped key fabricated.

The automatic bilge pump stopped working a few hundred miles west of San Diego. The propeller shaft seal leaks, so the pump runs fairly frequently. This turned out to be water intrusion into the spade connectors and was easily repaired.

A few days west of San Diego the wind vane got far enough out of adjustment that it was not effective. I had no real desire to disassemble the wind vane while hanging over the transom (I should have), so we switched over to the Raymarine autopilot.

It seemed that the batteries weren’t lasting as long as they should, when in fact motor on the ST 4000+ wheel drive was going bad. The motor eventually failed in the middle of the night while running downwind in 20 knots.

We ended up steering by hand for eight days. We learned that only one of us could be awake at a time. Sleep deprivation and the attendant hallucinations start pretty quickly.

Prophylactically replacing the ST 4000+ wheel drive unit turned out to be a ridiculously bad decision. In the course of failing, Caro Babbo jibed, exploding the cast bronze shackle holding the preventer in place, busting some of the welds holding the traveler in place on the cockpit table immediately in front of the wheel, and dragging the traveler 18 inches to starboard.

A cast bronze, rather than a forged bronze shackle, was a stupid oversight. I just grabbed the shackle out of our kit without a second thought. This shackle, like many of the shackles onboard Caro Babbo, is now Dyneema.

Because Jennifer’s car had been stolen a few days before we left, we did not have the original ST 4000+ wheel drive on board, so we could not cannibalize it for its motor.

When the car was recovered, the thieves left a number of fast-food wrappers in the front seat and the original wheel drive in the luggage compartment. They stole everything else that was not part of the car. We were very, very lucky that they had not stolen the car two or three days earlier when it contained two of our headsails and many of the parts that we needed, such as replacement lines and blocks. They did get the backup VHF radio, among other redundant hardware.

The bail on the boom vang failed just north of the Golden Gate heading to San Francisco. We took that as an omen and motored under the bridge rather than sailing as everyone wants to do.

On the leg from Seattle to San Francisco, we found that the autopilot was not as accurate as I expected. So, while we were in San Francisco I added a rudder position sensor, which made it a very large difference in the accuracy of the Raymarine autopilot.

Nearing the end of the Kuaui-Aleutians Island passage we started to have some electronics failures. The Iridium Go started acting up by not making connections to the satellite and not assigning IP addresses to devices that tried to connect. I assumed at the time, and continue to believe, that the problem was introduced in the latest firmware update. Removing the battery to completely power down the unit gets rid of the problem.

This is a known problem at PredictWind.

Our Vesper AIS started acting up as well. Basically, it would stop communicating. We noticed it first when the Raymarine control head would tell us that it no longer received course over ground and speed information. The radar also complained that it was no longer receiving positioning information – before we left Hawaii, it had started telling us that it was getting timeouts from the AIS. I ‘‘fixed’’ that problem by turning off the alarm.

Finally, the AIS would go off WiFi. This is an annoyance because we use the Vesper AIS’s GPS data for all of our handheld devices and laptops. It is only an annoyance, rather than a problem because all of the handheld devices have their own GPS, and we have a GPS puck for the laptop.

We communicated with Vesper while we were heading north. They said they thought it was probably something in the power supply given all three communications modules would fail. But, it never stopped transmitting AIS as indicated by the green light on the unit.

Vesper has an exchange program, where for a fee, they will send you a refurbished unit. But our unit was one of the first to be manufactured and shares so little hardware with the current model that they cannot offer the exchange program.

Both units are single points of failure; we should have two of each before we go offshore again.

The Isomat gooseneck is a marvelously designed piece of gear: easy to remove and wonderfully thought out. The problem is replacement parts. The only supplier is a Rhode Island company that manufactures seriously substandard replacement parts. The bearing I replaced in the gooseneck fractured putting too much pressure on one side of the gooseneck fracturing the bearing holder as well.

We ordered new bearings from Ed Louchard at Zephywerks. The products we receive from him are the highest quality I have seen. However, we needed to order a replacement gooseneck from the Rhode Island company. The gooseneck they shipped us was a new casting of a used gooseneck whose bearing holder was worn.

This has held so far, but the weight on the bearing is not even.

The raw water impeller pump shaft seal started to leak somewhere west of San Diego. I rebuilt the pump with new bearings in Ko Olina Marina on Oahu. Easy work, but expensive bearings.

Well after we arrived in the Aleutians, after Dutch Harbor and King Cove and Chignik, in a remote bay, the throttle control stopped shifting out of neutral. The quick fix was to disconnect the linkage and shift by hand, which we did. The new throttle control was inexpensive and easily installed. During the installation, I discovered that an idiosyncrasy in the throttle function was another failure within the throttle mechanism that happened before we bought the boat.

Dropping a key piece of electronics with a micro-B USB cord attached will break the connector, which is how we broke the connector on the Iridium Go several days east of Hilo. The broken connector allowed enough current to power the device but not enough to charge it. Once on Oahu we found Yoda, who saved the day. This linked post and the next tell about Yoda and failures on the way to Hawaii.

You and I, by now, are both too tired to read about cracking the casting on the engine starter sitting on the fuel dock in Ko Olina marine and lots of other minor and annoying things breaking. The linked post above will take you through everything that broke between Seattle and Oahu.

While the number of things that broke from Seattle to Hawaii was unsettling, it was nothing compared to boats we met in Hawaii. As Jennifer commented upon our arrival in the Aleutians, “We didn’t catch fire even once.” We met a vessel that was recently arrived in Ko Olina that had suffered a number of fires along the way. The man of the couple who sailed it broke into tears when he told Jennifer how close they felt they were to dying.

What we would add

Anemometer

Caro Babbo has no masthead instrumentation other than a Windex directional wind vane. My feeling is that the actual windspeed number is not important. When we’re out in the weather, we know how fast the wind is blowing. But, we’ve made all of the capital improvements to Caro Babbo we have planned, so there is now money for things that aren’t necessary, we might call them luxury doo-dads. This is one. I’ll be looking at solar-powered wireless devices that hopefully speak NMEA 0183 over WiFi

Battery monitor

Like the masthead wind vane, a battery monitor would be something to have. We judge our batteries’ fullness by the at-rest voltage. A monitor that measures wattage in and out might be fun.

However, on Caro Babbo, we use an automated A/B switch that joins the house and starting batteries when the voltage of either one rises above 12.9V for more than two minutes. Among other things, this allows the alternator to fully charge the starting battery before charging the house batteries. Would a battery monitor work with this configuration?

Immersion suits

We spend much of our sailing in waters that are 50F (10C) and below, oftentimes with ice floating alongside our hull. Immersion suits are things that make terrific sense and items we’ve wanted for some time. The prices have dropped precipitously in the last few years to below $400 apiece.

In the cold waters of British Columbia and Alaska, the true purpose of a PFD is to find the body of the person who fell overboard, not to save their life. Immersion suits change that formula, if we wear them. I’ve seen videos of Greenland sailors donning immersion suits whenever they get into a small dinghy. I don’t know how we’ll use ours.

*The device is perhaps one of the best mechanical devices, in terms of quality of construction and engineering, that I have ever owned. There are no gears. The quality of construction and the amount of machining made the product economically untenable, and that particular product was discontinued. The founder of the product, Stellan Knöös, is in his 80s and currently lives in San Diego. He is looking for a buyer for the company, if you’re interested.

† The Isomat mast has sockets for forward and aft shrouds in the spreader fitting.

**After a firmware up, the Iridium no longer works effectively as a router.

10-Oct-2020