5-FEB-2018, Port Townsend, WA – Premium Ropes has some very good videos on splicing. They are my go-to place for videos.

Last spring, while the mast was down, I replaced all the sheaves in the masthead, cut a new opening for an additional headsail halyard. I also installed a messenger line so that when the halyard was complete I could merely pull it up and through.

The messenger line turned out to be less than a great idea: if I had installed the halyard relatively quickly, let’s say within two months, it would have worked out quite well. Instead, we went sailing across the summer in all kinds of weather. The messenger line jumped out of the sheave and wedged itself between the sheave and the masthead casting. Oh well.

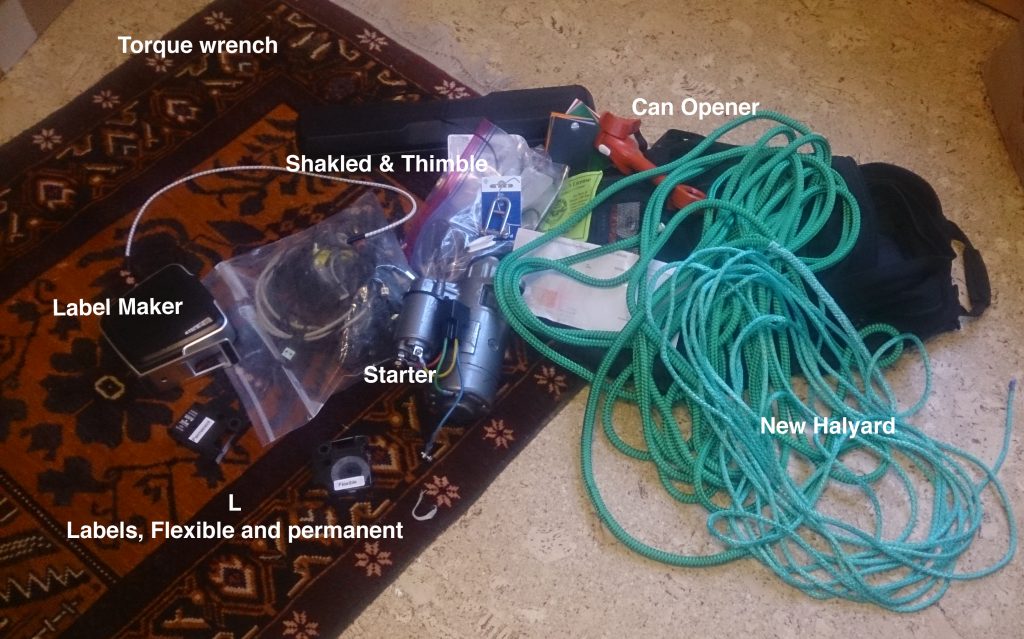

Last April, before we left, I bought the materials for the halyard: 45 feet of 5/16 inch dyneema line and 50 feet of 3/8 inch polyester line. Both are bright green.

I also bought a nylon thimble and a very good quality shackle to attach to the head of the headsail.

At the boat show I spent time with our sailmaker, Jim kitchen, who strongly recommended that, rather than using a traditional stainless steel shackle, I use a spool shackle from Tylaska. The Tylaska shackle is very cool, very lightweight and very ingenious. However, I need to do some measurements to understand how long the eye splice in the end of the halyard needs to be. The loop has to be large enough to go through the fitting on the head of the sail and move all the way back on itself while passing around the spool of the spool shackle.

At the boat show I spent time with our sailmaker, Jim kitchen, who strongly recommended that, rather than using a traditional stainless steel shackle, I use a spool shackle from Tylaska. The Tylaska shackle is very cool, very lightweight and very ingenious. However, I need to do some measurements to understand how long the eye splice in the end of the halyard needs to be. The loop has to be large enough to go through the fitting on the head of the sail and move all the way back on itself while passing around the spool of the spool shackle.

Lines like dyneema are called high modulus lines. They are as strong, or perhaps stronger than steel†, exceptionally lightweight and very easy to work with. They also don’t stretch, so you must choose the application correctly. Certain applications, like travelers and dock lines, require that the lines stretch. There are some very nice stories of people tearing their mainsheet travelers apart when they install dyneema lines rather than the typical polyester lines; polyester lines are chosen because they don’t stretch… much. Polyester lines are called low stretch, where dyneema, for all intents and purposes, doesn’t stretch at all.*

On Saturday, I watched the video on joining a dyneema halyard to a polyester tail a few times and was quite certain I understood the steps.

When splicing three-plait lines, the process is merely braiding the lines together. It’s easy, low tech and really quite relaxing. The finished product is quite transparent in terms of the work that was done and fairly attractive, to be honest.

Splicing braided line is quite a bit different. Braided lines are essentially braided tubes of fiber. Splicing is a matter of inserting tubes one inside another. The way this ends up being done in practice is certainly not intuitive to me and very much has the feeling of being shown how a magic trick works.

When I saw the video was nine minutes long, I figured it would take me about an hour to do the splice. Though I’m not entirely certain that it took me nine hours to do the splice, it did certainly take me more than six.

The problem can be solely attributed to not having the correct tool to do the work. When placing one of the tubes that makes up a line into another, the line can be pulled or pushed. If pushed the end of the tube going into another tube is placed inside a hollow, round pointed aluminum rod and slid through. I generally tape the line to the rod.

Another method is to use what is called a D-tool, which is really a bent piece of wire with a handle. The D tool is used to pull the inner tube through the outer tube.

In this instance, all of the tubes of line being pulled through the dyneema line are in fact larger diameter than the dyneema line itself. This made the operation a very tight fit. The aluminum rod, which I normally use, was just too tight a fit to push through the dyneema. In fact, anything that used tape to hold the inner line to the tool was such a tight fit that the adhesive would get squeezed out of the overlapping tape and stick to the inside of the dyneema.

I didn’t have a D-Tool and one was not available to buy. Looking at the mechanics of the tool, there doesn’t seem to be a need to buy one, in any case. However, the smallest solid core wire that I could find was 14gauge. This seems to be just too thick: when added to the thickness of the line folded into the loop of wire, I had one hell of a time pulling it through. It is also possible that 3/8 inch polyester line is just difficult to splice to a 5/16 inch dyneema line. Good expertise on this is difficult to find.

I found that I could pull the polyester line through the dyneema for about seven or 8 inches of the nineteen or 24 inches I needed to pull it through. After that there was not enough slack in the braid to expand the dyneema wide enough to pull polyester through. I had to move each strand of the twelve strand dyneema over the end of the polyester tube that I was pulling. It was a process that took an hour to an hour and a half both times I did it. Much of the rest of the time was trying different techniques, none of which were successful.

By 6 PM, I had a successful, though perhaps not as professional looking a splice as I would with a little bit of practice. I also had a blister and the soreness of soft, uncalloused hands doing labor that requires and will develop callouses.

Today, Monday, I’ll do some more desk work, measure the insignia that we put on our older mainsail so that we can replicate it on the new mainsail – the insignia that came with the new mainsail is very small and missing the two bars under the insignia that indicate the boat is a Maxi 95.

Today, the solid-state drive (SSD) for my laptop will finally arrive. I haven’t replaced it earlier because the budget just did not have room for this type of expenditure: $700 for a 1 TB solid state drive. So I have been using my Mac with a mechanical disk drive at the end of a USB cord. It is a serious nuisance to have an external drive and terrifyingly slow because the current Mac OS is designed for an SSD.

Today, the solid-state drive (SSD) for my laptop will finally arrive. I haven’t replaced it earlier because the budget just did not have room for this type of expenditure: $700 for a 1 TB solid state drive. So I have been using my Mac with a mechanical disk drive at the end of a USB cord. It is a serious nuisance to have an external drive and terrifyingly slow because the current Mac OS is designed for an SSD.

By staying here for a week, rather than return last Tuesday as I planned, I will return with a very full backpack of things to carry (I’ve been on a small shopping spree via Amazon).

The major items to be accomplished when I return to the boat are:

- Reinstall the starter with the additional relay

- 2000 hour engine maintenance – this will include dealing with the head bolt that seems to be stretching. Hopefully in my notes I will be able to tell which one it is and be able to remove it without breaking it off.

- Replace the mainsheet traveler and mainsheet. The car has been spewing ball bearings and pieces of its wheels since early May.

- Purchase and install the engine kill cable

- Install new jib halyard – this is lower priority and requires someone to help me up the mast. Though, I am considering building a rig to pull myself up the mast. The correct rigging to use the Portland Pudgy as a life raft requires 150 feet of line. I think this might be an amount that could serve double duty as a rig to take me up the mast.

- Use the new label maker to replace all the labels on the fuse box – they are very difficult to read and I haven’t memorized the location of some of the switches I use less often.

Now that I’m working on the boat and will be aboard the pace of posts will increase, though they will remain maintenance oriented for quite a while.

By doing all this boat work, Jennifer and I are not sailing Caro Babbo and are missing the winter sailing we enjoy so much.

†We’ve seen the phrase ‘‘stronger than steel.’’ That phrase is usually in reference to weight, as in ‘‘pound for pound, stronger that steel.’’ Dyneema, and other high modulus fibers are stronger in size. A ¼” dyneema line is stronger than a ¼” steel cable.

*Interestingly, dyneema lines, which are twelve-strand braids, are not recommended as lifelines because the braids stretch. Once all the stretch is taken out of the braid, the fibers will not stretch, but apparently life line installations do not have enough tension in them to remove the stretch from the braid.